Home > News

Home > News

Introduction to the principle of filtration and dust removal - Changzhou Wayon

The settling mechanism of dust particles such as inertia collision, interception, diffusion, gravity and electrostatic force is the theoretical basis for analyzing the dust mechanism of filter filter.The dust filtration process of the filter filter is relatively complex. Generally speaking, the settlement of dust particles on the collection collective, namely separation and filtration, is not only a kind of settlement and filtration mechanism in action, but the result of the combined action of a variety of settlement and separation and filtration mechanisms.

According to the different mechanical properties of dust with different particle sizes in the fluid, the filtration and dust removal mechanism involves the following aspects:

1.1.1 sieve action

Generally, the mesh size of the filter material is 5 ~ 50 m. When the dust particle size is larger than the mesh or pore diameter or when the dust is deposited in the gap between the filter materials, the dust is blocked and left behind.For the new fabric filter material, due to the gap between the fibers, that is, the pore size is much larger than the dust particle size, the filtration effect is very small, but when a large amount of dust is deposited on the filter material surface and forms a dust layer, the filtration effect is significantly enhanced.

1.1.2 inertial impact

Generally, dust with larger particle size is mainly collected by inertial collision.When the dust flow is close to the fiber of the filter material, the airflow will bypass the fiber, among which the larger particles (more than 1 m) will deviate from the flow line of the airflow due to the action of inertia, continue along the original direction of motion, hit the fiber and be trapped.All the large dust particles in the dust track boundary can reach the fiber surface and be trapped.The inertial impact increases with the increase of dust particle size and airflow velocity.Therefore, increasing the flow velocity through the filter material can improve the inertial impact.

1.1.3 interception

When the dust flow is close to the filter fiber, the finer dust particles will flow with the flow. If the dust radius is greater than the distance between the center of the dust particles and the edge of the fiber, the dust particles will be intercepted because of the contact with the fiber.

1.1.4 diffusion

For dust particles less than 1 m, especially submicron particles less than 0.2 m, they break off the streamline under the impact of the gas molecules, and move like the gas molecules in Brownian motion. If they contact with the fiber during the movement, they can be separated from the airflow.This effect is called diffusion, and it increases with the decrease of flow rate and the decrease of fiber and dust diameter.

1.1.5 electrostatic action

Many fiber woven filter material, when the airflow through the produce electrostatic phenomenon, because of friction and dust in the process of delivery will be charged due to friction and other reasons, it will in the filter material and form a potential difference between dust particles, when the dust with air filter material trend, because the coulomb force to dust and collisions and increase of filter material fibre was arrested for dust adsorption force, improve the efficiency of capture.

1.1.6 gravity sedimentation

When the slow-moving dusty airflow enters the dust collector, the dust particles with large particle size and density may naturally settle down due to the action of gravity (see table 1-1).

Table 1-1 shows the granularity range of various trapping mechanisms.

NO | mechanism | particle size range | Effect of increased wind speed on mechanism efficiency

|

NO | mechanism | particle size range | Effect of increased wind speed on mechanism efficiency

|

l | intercept | >1μm | 4 | Electrostatic | <0.01~5μm | reduce | |

2 | Inertia collision | >1μm | rise | 5 | screen | Filter layer micropore size

| |

3 | diffusion | <0.01~0.5μm | reduce |

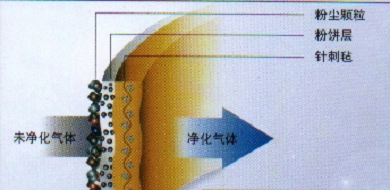

Generally speaking, various dusting mechanisms are not effective at the same time, but one or several combinations of them.In addition, with the change of air gap, air velocity, dust particle size and other reasons, various mechanisms have different effects on the filtration performance of different filter materials.In fact, the new filter material at the beginning of the dust filter, the dust removal efficiency is very low.After a period of use, the coarse dust will form a dust layer on the surface of the filter cloth.FIG. 1-1 dust filtration process of press cloth.Due to the dust effect of the initial layer and the dust layer gradually accumulated on it, the filtration efficiency of the filter material is constantly improved, but the resistance is also correspondingly enhanced.In the ash, can not destroy the initial layer, otherwise the efficiency will decline.The structure of the dust primary layer plays a very important role in the efficiency, resistance and ash removal of the bag filter.

Figure 1-1