Home > News

Home > NewsChangzhou Wayon PTFE series products -PTFE membrane filter material

The surface smoothness of the filter material has great influence on the dynamic resistance of the filter material. The initial resistance of the filter material depends on the permeability of the filter material itself, and the resistance in operation is many times greater than the initial resistance. Running resistance depends on the degree of the smooth surface of the filter material, ash removal effect, etc., general hope filtering material in the guarantee equal filtration efficiency, air volume is bigger, the better, that is, the lower the resistance, the better, because this can save a lot of energy, in the use of air blow dust precipitator, at the same pressure, the same air volume of air flow for ash removal, selection of large quantities of breathable weaving material when making filter bag, the effect is better to choose breathable small weaving.

PTFE (Polytetrafluoroethylene) film has a smooth surface and is resistant to chemical substances. It is coated to the surface layer of ordinary filtration materials to play the role of a one-time dust layer, and all dust is trapped on the surface of the film to achieve surface filtration.Because the film surface is smooth, there is excellent chemical stability, not aging, and hate water, so that the dust trapped on the surface is easy to flake, and improve the service life of the filter.

Compared with ordinary filter materials, it has the following advantages:

1. The filtration efficiency of the film is 99.99% with pore diameter of 0.23 m and almost zero emission.The dust removal efficiency is always high without changing the porosity.

2. At the beginning of the use of coated filter material, the pressure loss is higher than that of ordinary filter material, but in the operation, the pressure loss with the use of time increases little, and the pressure loss of ordinary filter material will increase with the extension of the use of time.

3. In the use of ordinary filter material, dust can easily enter into the interior and accumulate more and more until the pores are blocked and can no longer be used.By using PTFE membrane filter material, the filtered dust can be easily removed from the film surface, with good ash cleaning effect, long cycle and low ash cleaning pressure strength, thus improving the service life of the filter material and reducing the operating cost of the product.

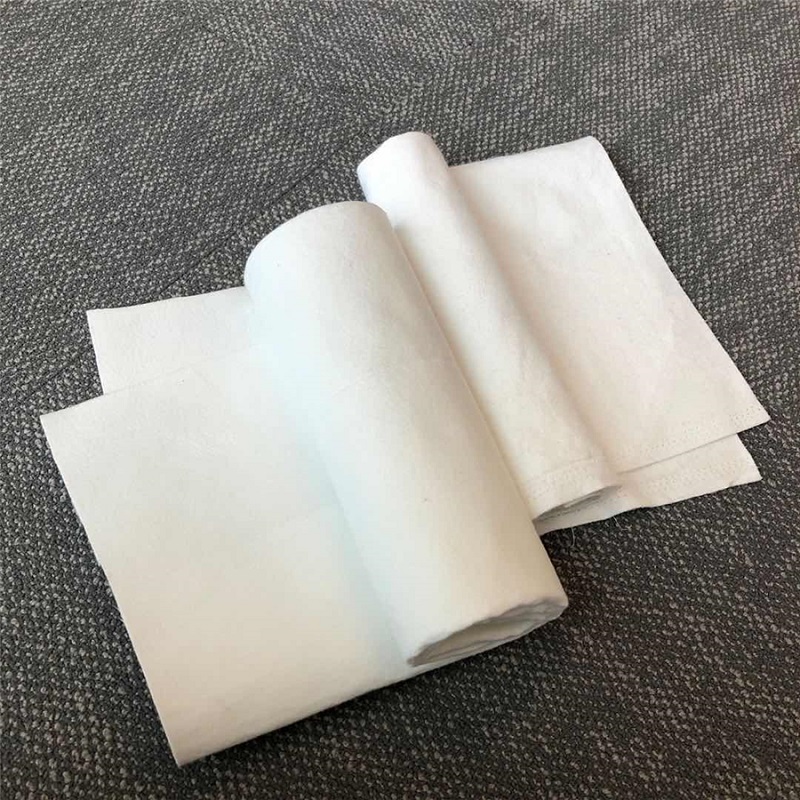

Changzhou Wayon selected high quality PTFE microporous film at home and abroad, and covered it with woven filter material and needling non-woven filter material to make PTFE film-covered filter material, which is widely used in flue gas purification, dust treatment and material recovery and other fields.